Sheet Metal Piercing

Why Total Metal Products?

As a sector leading machine design and tool making company Total Metal Products (TMP) supplies high quality stretch bending tooling systems and has the in-house capability to design, manufacture, commission and service your stretch bending requirements.

Sheet Metal Piercing Solutions

As a sector leading machine design and tool making company, Total Metal Products (TMP) have been designing, manufacturing, commissioning and servicing production processing systems which include sheet metal piercing operations.

TMP are a leading machine design and tool making company, continually delivering high quality production manufacturing solutions across multiple industry sectors and business sizes.

Our sheet metal piercing solutions are designed to maximise the workplace ergonomics, ensuring the workplace fits the needs of the worker, rather than the worker having to adjust to the workplace.

TMP are experienced with using traditional and where demanded our high-quality solutions extends to the use of cutting-edge materials, design and material handling techniques to maximise production line uptime and reduce maintenance costs.

TMP also deliver production automation solutions. If you are interested in automating your production line, we have an extensive knowledge of, and experience in, providing robotic / automation solutions.

Automated Solutions

If your manufacturing operation demands consistency and accuracy of metal forming piercing, TMP can provide an integrated robotic press or automated manufacturing solution.

Our automated solutions are designed to your exact requirements, tolerances and specifications, or the solution can be retrofitted to your existing operation.

Our sheet metal piercing solutions are designed, manufactured and assembled in-house. With extensive industry experience our team of designers, project management and production engineers, work together to produce the most effective metal piercing solution which meets your business requirements. We always deliver our solutions on time and on budget.

We design and manufacture a range of production line process equipment e.g. stretch forming, stretch bending, roll forming, assembly jigs etc, which sit either side of the metal piercing operation.

With our extensive experience across a broad range of technologies and industries we are able to provide you with the optimum solution for your production requirements.

A key objective of our sheet metal piercing solutions is that they are designed to minimise production errors due to misalignment, waste blockage, tool breakage etc.

Misalignment during the piercing function causes problems both in production and post production, increasing the level of production rejection and poor quality increases the financial burden on the business, ultimately impacting your profitability and adding to your environmental impact.

If your business has a requirement for prototype, low volume or end-of-life manufacturing our group partner company TMP Manufacturing can provide your business with solutions to meet these challenges.

At TMP Manufacturing we are able to produce your low volume requirements, to schedule, with management of your raw material supply chain if required; we also provide finished product storage and onward delivery to your customer using your systems, packaging and paperwork.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What is Metal Piercing?

Piercing is the process whereby the raw material is pierced with a machining tool, via shearing, which results in the creation of a hole with the dimensions and profile of the tool / blanking punch and associated die. The raw metal which has been pierced is considered scrap and recycled.

There are a number of different piercing processes, which include the following:

- Lancing

- Trimming

- Notching

- Perforating

TMP can produce a broad range of toolmaking solutions.

We have extensive experience in:

- Stretch Forming

- Stretch Bending

- Roll Forming

- Welding Jigs

- Assembly Jigs

- Metal Punching

- Toolmaking Design

- Toolmaking

- Tool Room Services

- Contract Manufacture

Supporting the world’s biggest brands

New Capabilities

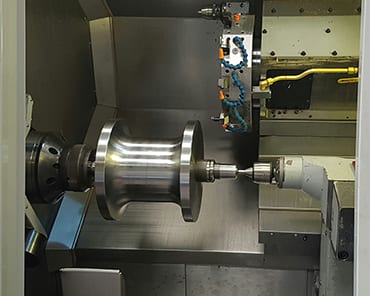

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management